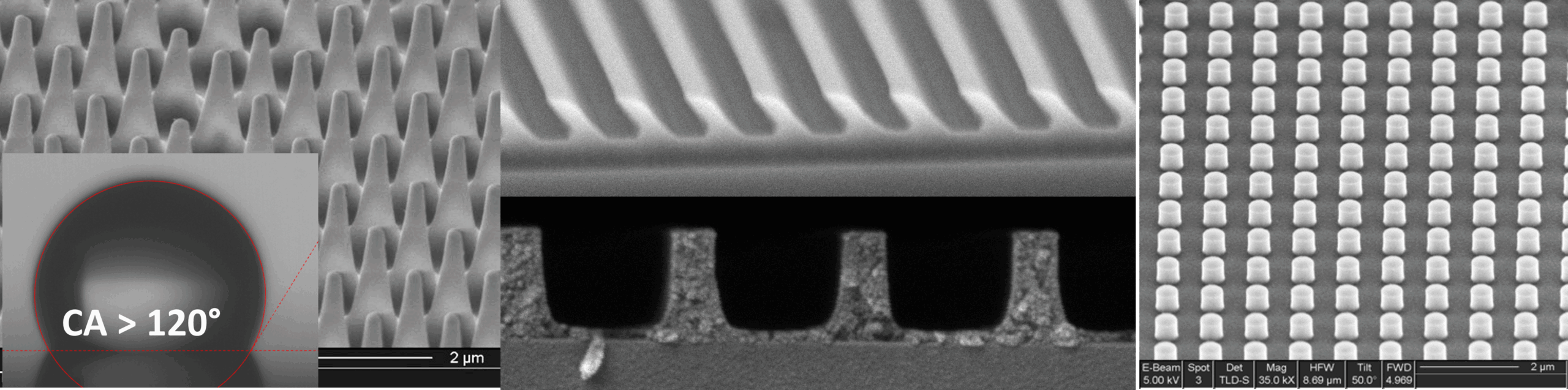

METAPRINT “Nano-imprint lithography of titania-based meta-optics” targets the nano-fabrication of near eye displays for augmented reality smart-glasses by direct printing hard ceramics (e.g. TiO2).

It will deliver Photonic Meta-surfaces capable of redirecting virtual images from a micro-display to the eyes.

GROUND-BREAKING TECHNOLOGY

TO UNLOCK THE “SMART GLASSES” MARKET

SOLNIL’S PATENTED TECHNOLOGY LEVERAGES EXTREME MATERIALS

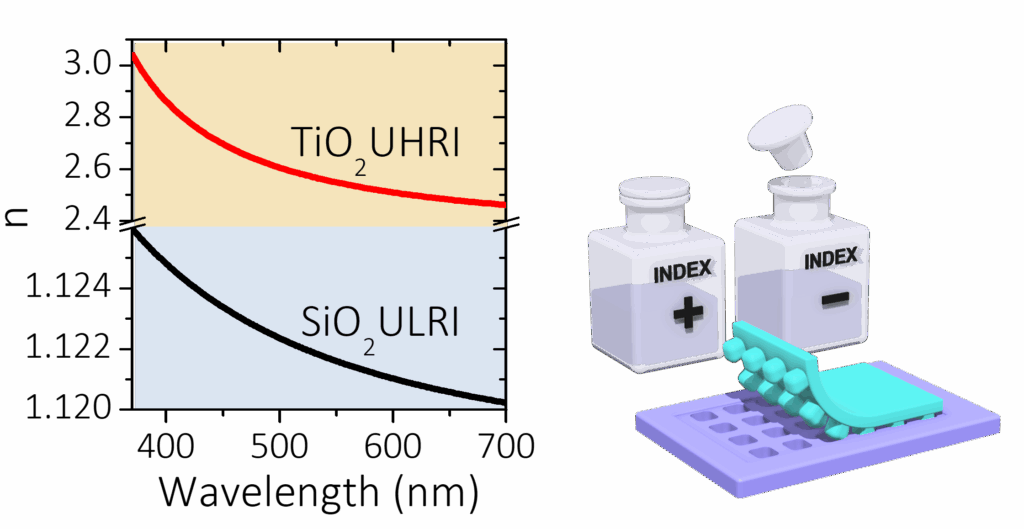

Printable inorganic resist: TiO2 with a ultra-high refractive index (UHRI, RI up to 2.6) and Ultra-low refractive index SiO2 (ULRI, RI down to 1.12).

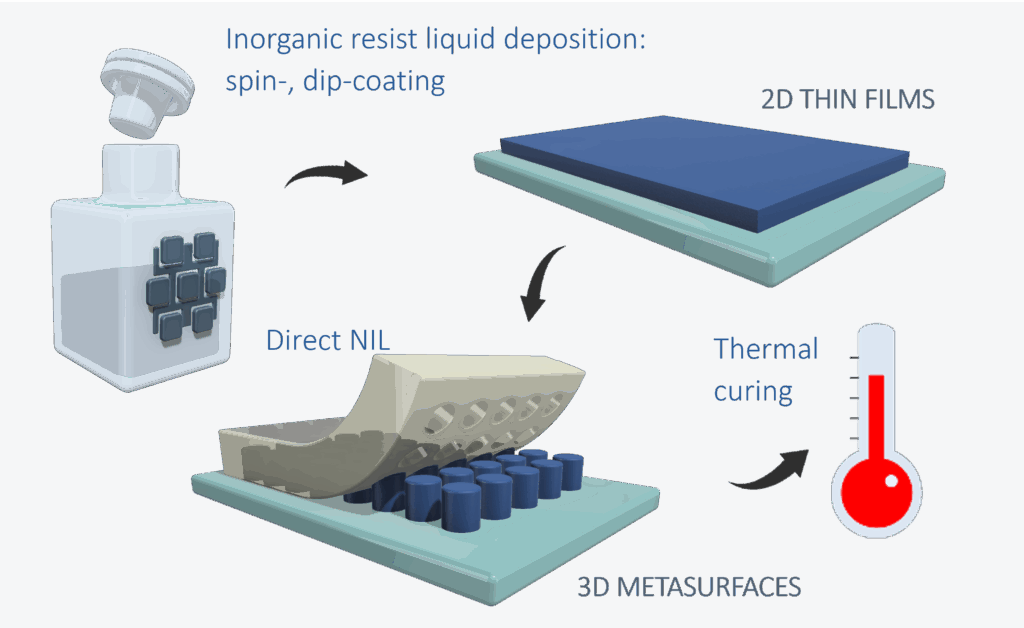

Spin- or dip-coating, at room temperature and atmospheric pressure of ultra-high RI (UHRI) and ultra-low RI (ULRI)

SOLNIL’s solutions are fully miscible in any proportion

LARGE AND FINE TUNEABILITY OF RI FROM 1.12 TO 2.6 +/- 0.005 RIU

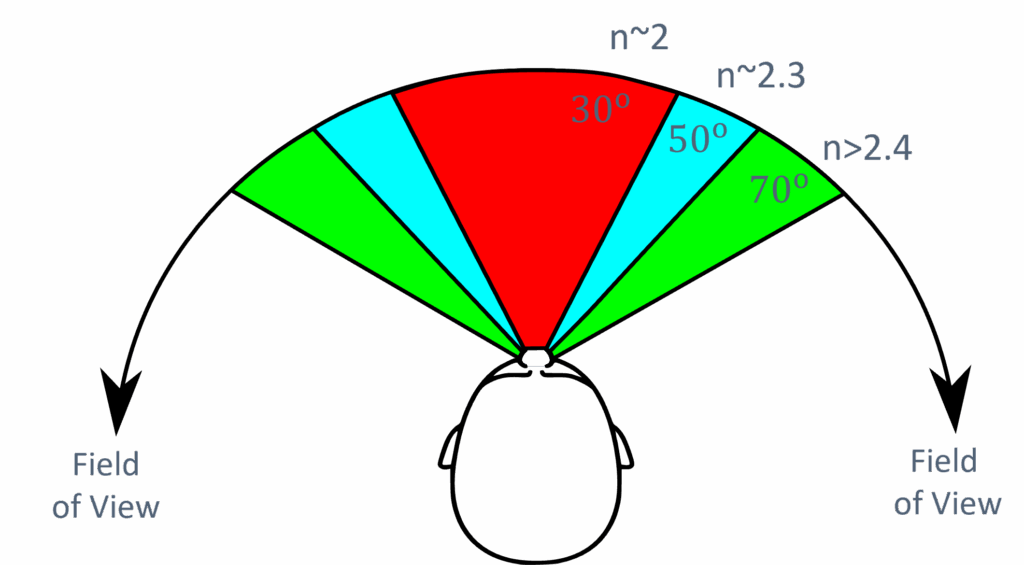

REFRACTIVE INDEX (CONTRAST) AND FIELD OF VIEW FOR AR

Larger RI contrast improves the field of view of smart glasses

TiO2 with RI up to 2.6

(e.g. the same RI of SiC)

SiO2 down to RI = 1.12

Field of view of virtual images increased by 40% with respect to current offers

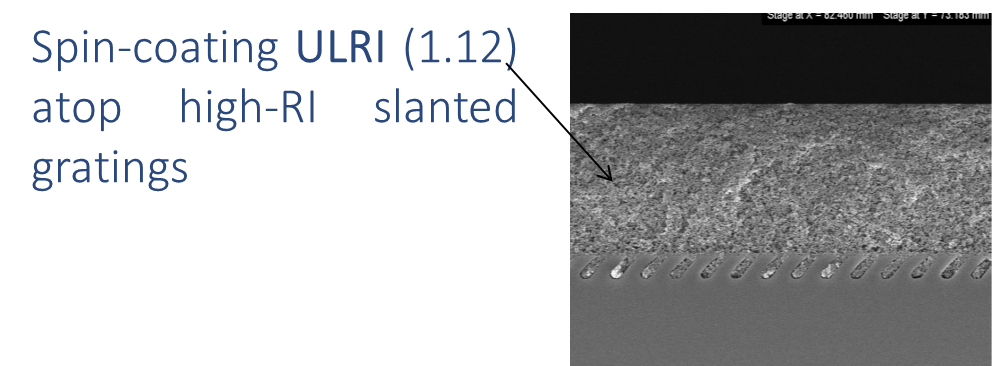

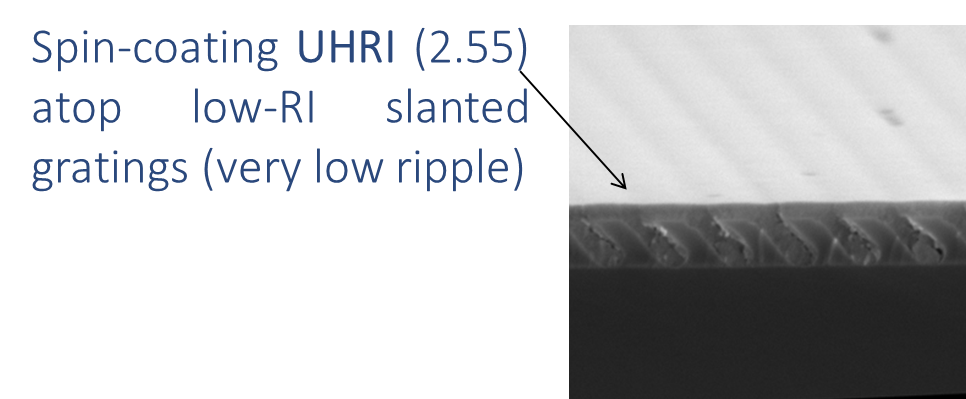

LIQUID DEPOSITION VIA SPIN COATING CAN BE USED ONTO 3D STRUCTURES PREVIOUSLY ETCHED BY CONVENTIONAL TOP-DOWN METHODS

DIRECT PRINTING OF PRINTABLE RESISTS PRODUCES 3D PATTERNS AVOIDING TOXIC AND EXPENSIVE ORGANIC RESISTS FOR LITHOGRAPHY, LIFT-OFF STEPS, AND ETCHING STEPS

FOR 2D FILMS:

NO VACUUM, NO DANGEROUS PRECURSOR GASSES

FOR 3D META-SURFACES:

NO UV, NO LIFT OFF, NO ETCHING

JUST DIRECT PRINTING OF THE FINAL STRUCTURES MADE OF INORGANIC MATERIALS

HIGHER SUSTAINABILITY

Beyond the superior performances of our material, we provide a massive reduction of both CapEx (>50 times) and CoO (>4 times) with respect to the incumbent top-down lithographic methods

SOLNIL has freedom to operate in this field and is already servicing several leading actors in the AR market by providing the technology for near eye displays based on diffractive waveguides.

METAPRINT will go beyond this common approach adopting Photonic Meta-surfaces to:

- Enhance the light management efficiency (extending the battery lifetime)

- Improve spatial resolution of the virtual images

- The colour brightness

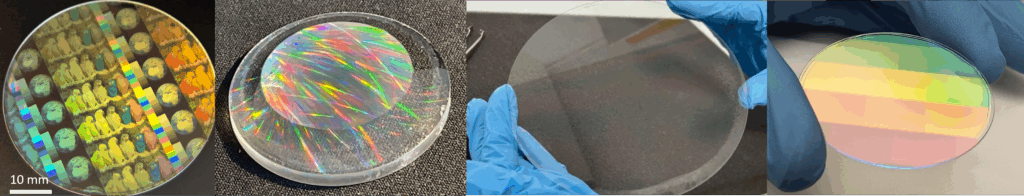

METAPRINT will showcase the viability of our approach by building a pilot-production line of near eye displays over 200 mm flat wafers and on 100 mm curved ones

METAPRINT RESULTS WERE PRESENTED IN THESE OCCASIONS:

- Direct Nano-imprint Lithography: Precision Patterning of purely Inorganic Compounds for Advanced Optical Materials

7th of March, TechBlick 6-7 March 2025, https://lnkd.in/eGK_Tv7x

- Touch Taiwan 2025 (https://lnkd.in/dKEvbnjj), a great event to meet the rich Taiwanese Display Ecosystem

- Nano-Imprint Lithography of Metal Oxides: Materials and Nano-Fabrication Methods for Photonic Metasurfaces

OPTICA OIC Conference (Tucson, USA) https://www.optica.org/events/topical_meetings/optical_interference_coatings/

- LASER WORLD OF PHOTONICS Trade fair. Messe München Congress: June 22–27, 2025 ICM–Internationales Congress Center München https://www.linkedin.com/company/laserworldofphotonics/

- Materials and direct nano-imprint lithography for high power lasers optics

EPIC Technology Meeting on Industrial Laser Processes at Optoprim (Milan, 10-11 September 2025)

https://epic-photonics.com/events/epic-meeting-on-industrial-laser-processes-at-optoprim/

MARCO ABBARCHI, CSO at SOLNIL, marco.abbarchi@solnil.com

Pépinière d’entreprises Luminy Biotech, 163 avenue de Luminy, 13011 Marseille France