Anti-reflective optical components for glass covers, imaging and high power lasers

SOLNIL has undertaken a step beyond in the anti-reflective coatings (ARCs) industry leveraging on the best combination of sol-gel inks and nano-imprint lithography of metal-oxides (MOx-NIL). Our nano-fabrication process addresses the main issues affecting conventional approaches (usually by photolithography, and plasma etching) reducing pollution and CO2, and improving safety in production. This direct moulding process of hard ceramics is compatible with plate-to-plate and roll-to-plate fabrication, improving productivity and cutting production costs.

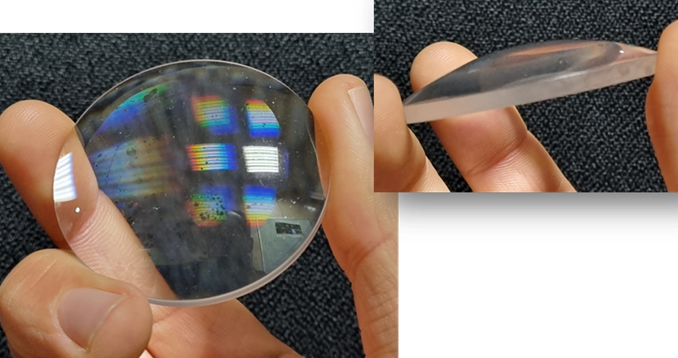

Thanks to its transparency, thermal stability and mechanical robustness, glass is the material of choice for micro and nanostructured optical components when temperature changes, harsh environment and high laser powers are involved. For LIDARS, optical devices for laser beam managing must handle large temperature range. Laser system integrators need optics and ARCs that can handle high power to improve the performances of their tools. Display manufacturers need robust ARCs coatings to improve the readability. Photovoltaic ARCs coatings compatible with outdoor can increase the yield of light-to-electricity conversion. Other relevant applications of SOLNIL’s ARCs are glass covers for imaging, lightening, detection, telecommunication, and quantum optics.

Beyond pure silica, SOLNIL has developed other metal-oxide materials transparent from near-UV to MWIR adapted to high-quality 2D optical coatings as well as a fabrication process to frame them in 3D structures. By changing the properties of the printable sol-gel inks, many different materials can be obtained[i], adapting their refractive index from 1.17 to 2.7 with a precision better than 0.01 RIU, while keeping high transparency and low scattering losses. Available materials for ARCs include: SiO2, TiO2, Al2O3, HfO2, ZrO2 and combinations thereof. They can be obtained both as 2D thin films and 3D structures, and are compatible with a plethora of substrates including glass, fused silica, sapphire and much more.

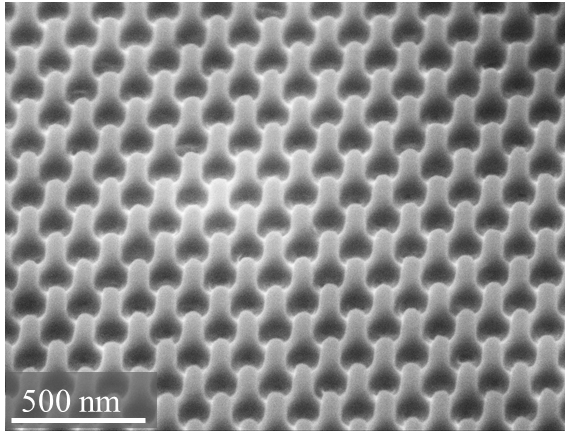

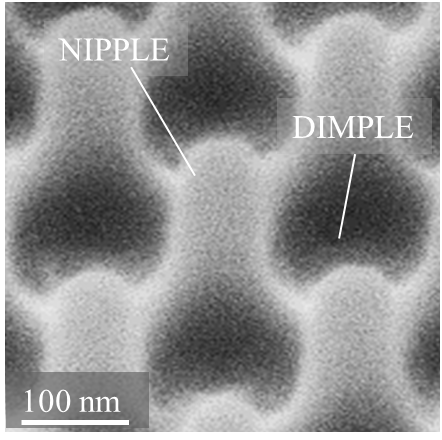

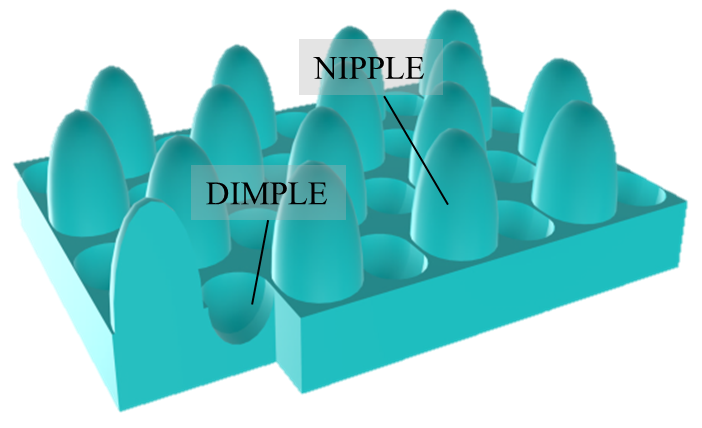

Thanks to the versatility of MOx-NIL the working range of our broad-band and wide-angle ARCs can be adapted to specific wavelength intervals by adjusting size and period of the 3D structures (e.g. the size of the 3D structures can be tuned in a very broad range, covering three orders of magnitude, from ∼10 nm up to ∼10 μm[ii]).

Our nano-imprint process is compatible with curved surfaces (e.g. lenses with radius curvature up to 54 mm) and it produces structures with high chemical, thermal and mechanical stability[iii].

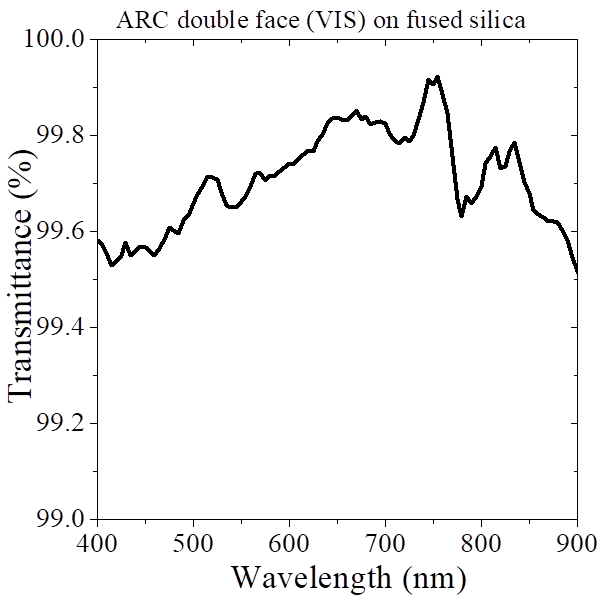

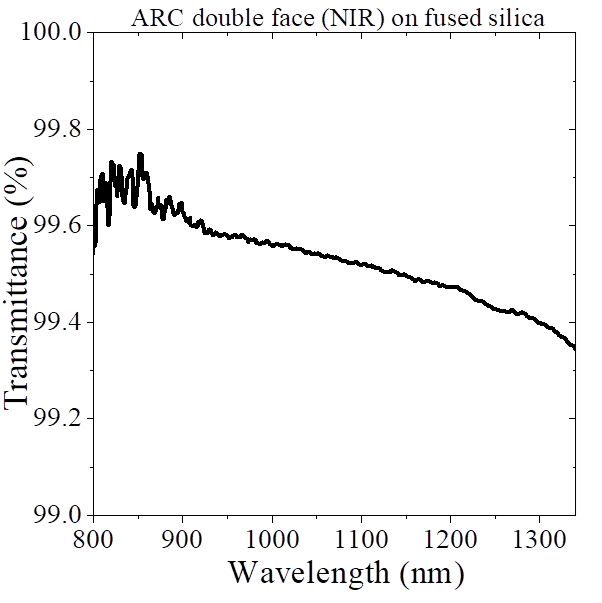

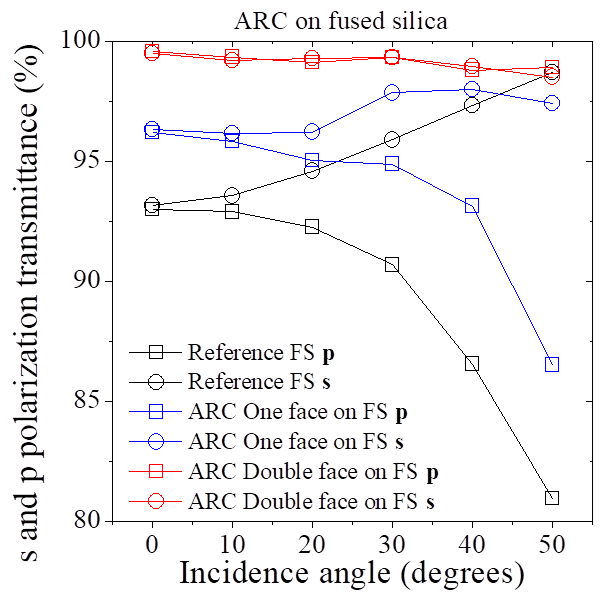

Typical performances of our double-face ARCs on fused silica:

99.5% < T < 99.8% from 390 to 900 nm

99.4% < T < 99.7% from 800 to 1300 nm

T > 99% up to 50 degrees for p and s polarization

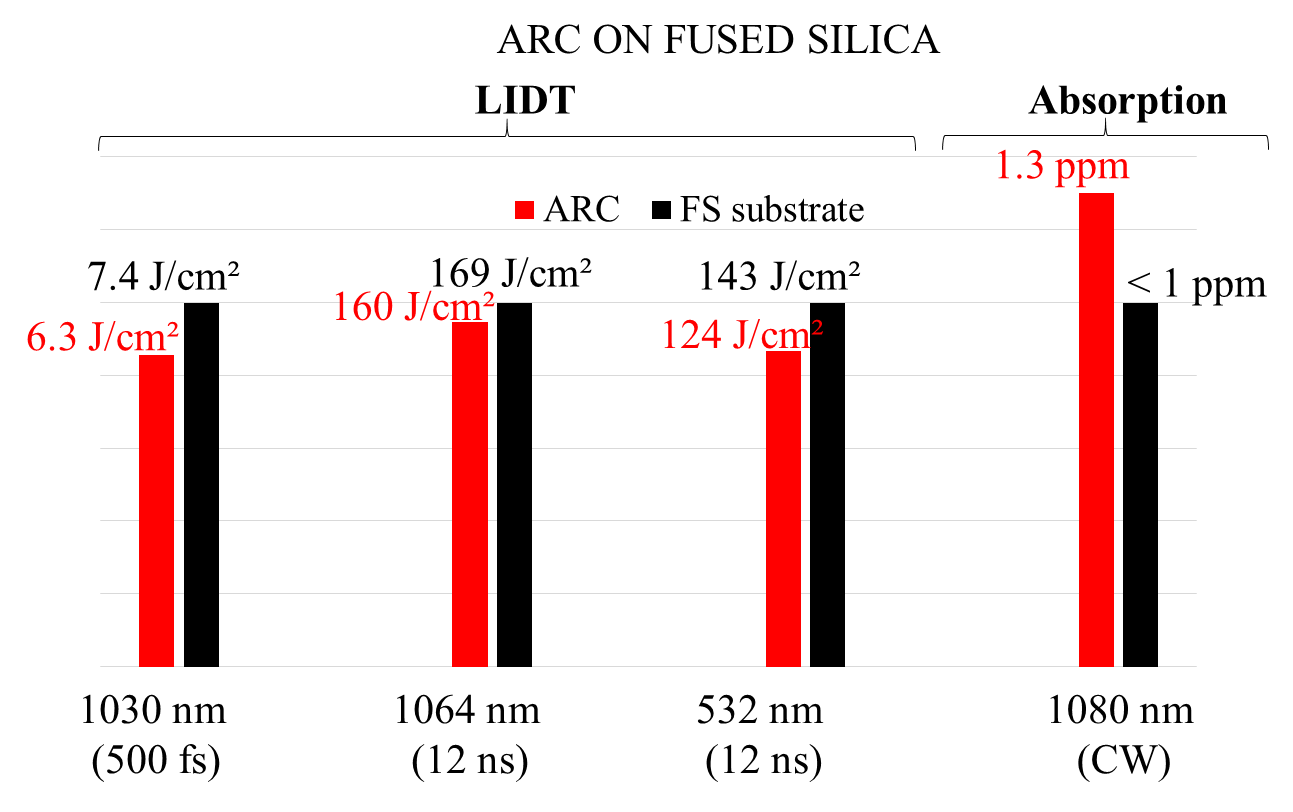

Laser induced damage threshold and absorption

Our ARCs were tested with high-power lasers[iv]. Typical values of the laser induced damage threshold (LIDT) are:

LIDT > 6 J/cm2 at 1030 nm, 500 fs

LIDT > 160 J/cm2 at 1064 nm, 12 ns

LIDT >120 J/cm2 at 532 nm, 12 ns.

Absorption < 1.3 ppm at 1080 nm, CW

All these values are close to those of the fused silica substrate accounting for the high quality of our ARCs.

---

[i] T. Bottein, O. Dalstein, M. Putero, et al., “Environment-controlled sol–gel soft-nil processing for optimized titania, alumina, silica and yttria- zirconia imprinting at sub-micron dimensions,” Nanoscale 10, 1420–1431 (2018)

[ii] Z. Chehadi, M. Bouabdellaoui, M. Modaresialam, et al., “Scalable disordered hyperuniform architectures via nanoimprint lithography of metal oxides,” ACS Appl. Mater. & Interfaces 13, 37761–37774 (2021)

[iii]Bochet-Modaresialam, M., Claude, J. B., Grosso, D., & Abbarchi, M. (2020). Methylated silica surfaces having tapered nipple-dimple nanopillar morphologies as robust broad-angle and broadband antireflection coatings. ACS Applied Nano Materials, 3(6), 5231-

[iv]M. Modaresialam, N. Granchi, M. Stehlik, et al. "Nano-imprint lithography of broad-band and wide-angle antireflective structures for high-power lasers." Optics Express 32, 12967 (2024)