The sol-gel chemistry combined with NIL processing

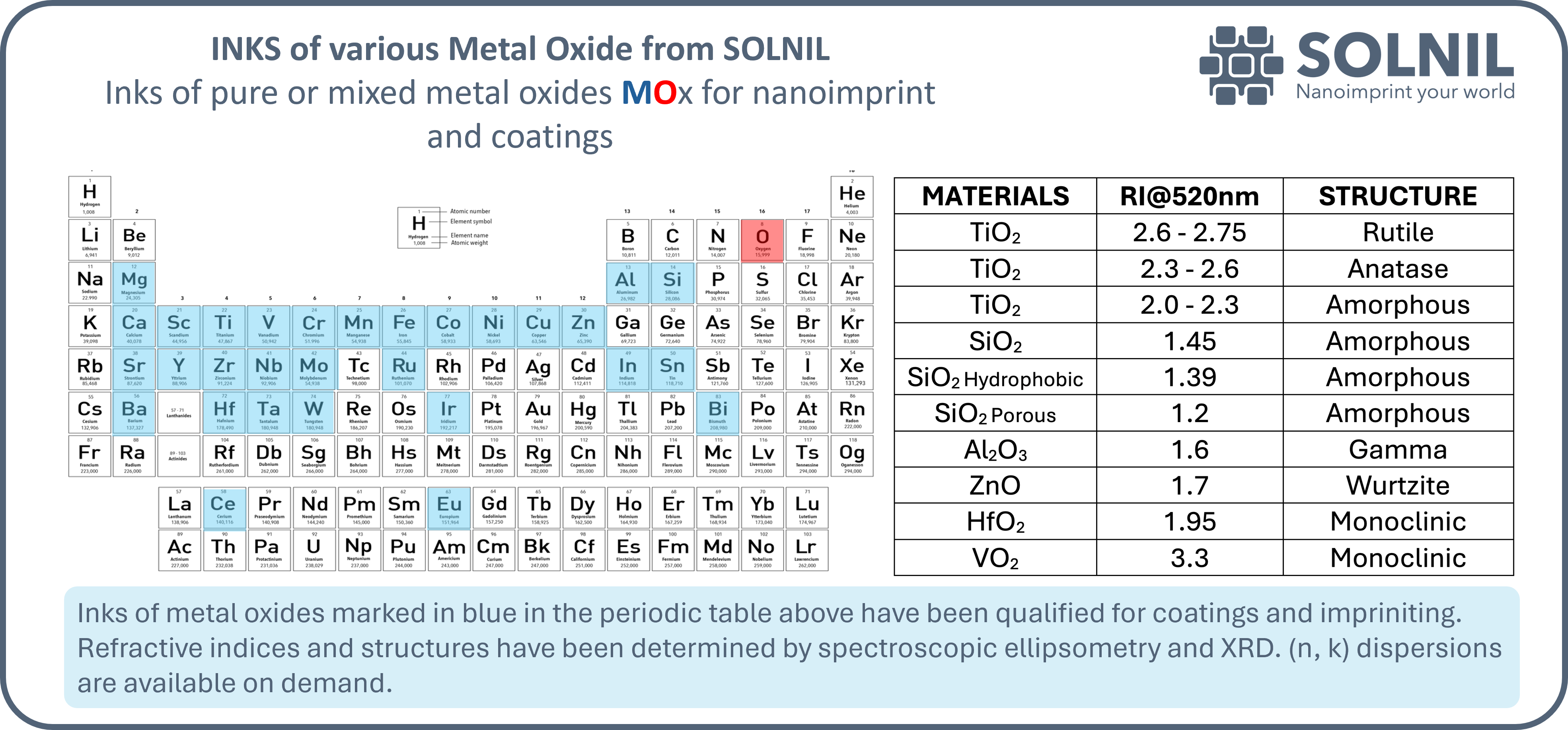

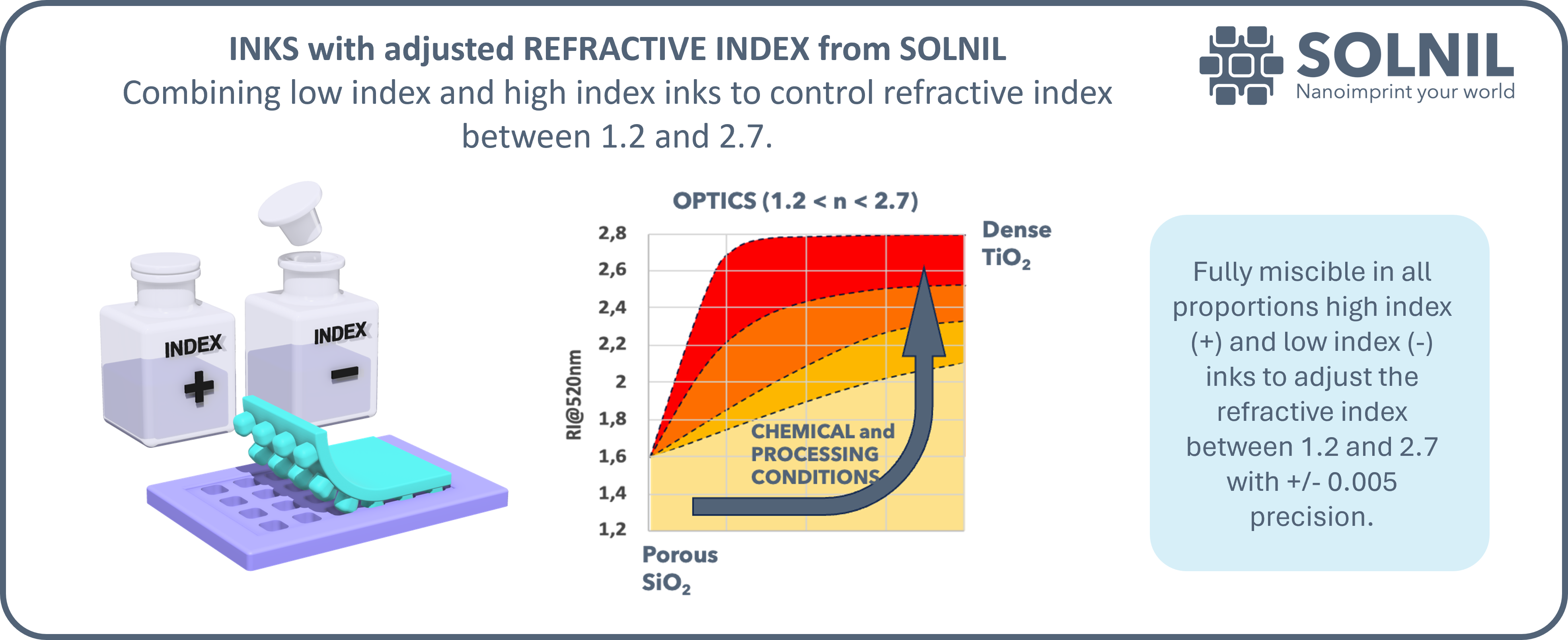

Sol-gel chemistry is based on hydrolysis and condensation of metal oxide precursors in solution. The intermediate products are polycondensed oxo-hydroxo nano-building blocks suspended in a solvent. Shaping the final sol-gel material from such nano-building blocks consists in processing the solution so that the evaporation of the solvent leads to spatial gathering of the blocks into the final morphology. A final annealing is applied to stabilize the material. This approach is conventionally used to prepare thin coatings by liquid deposition.

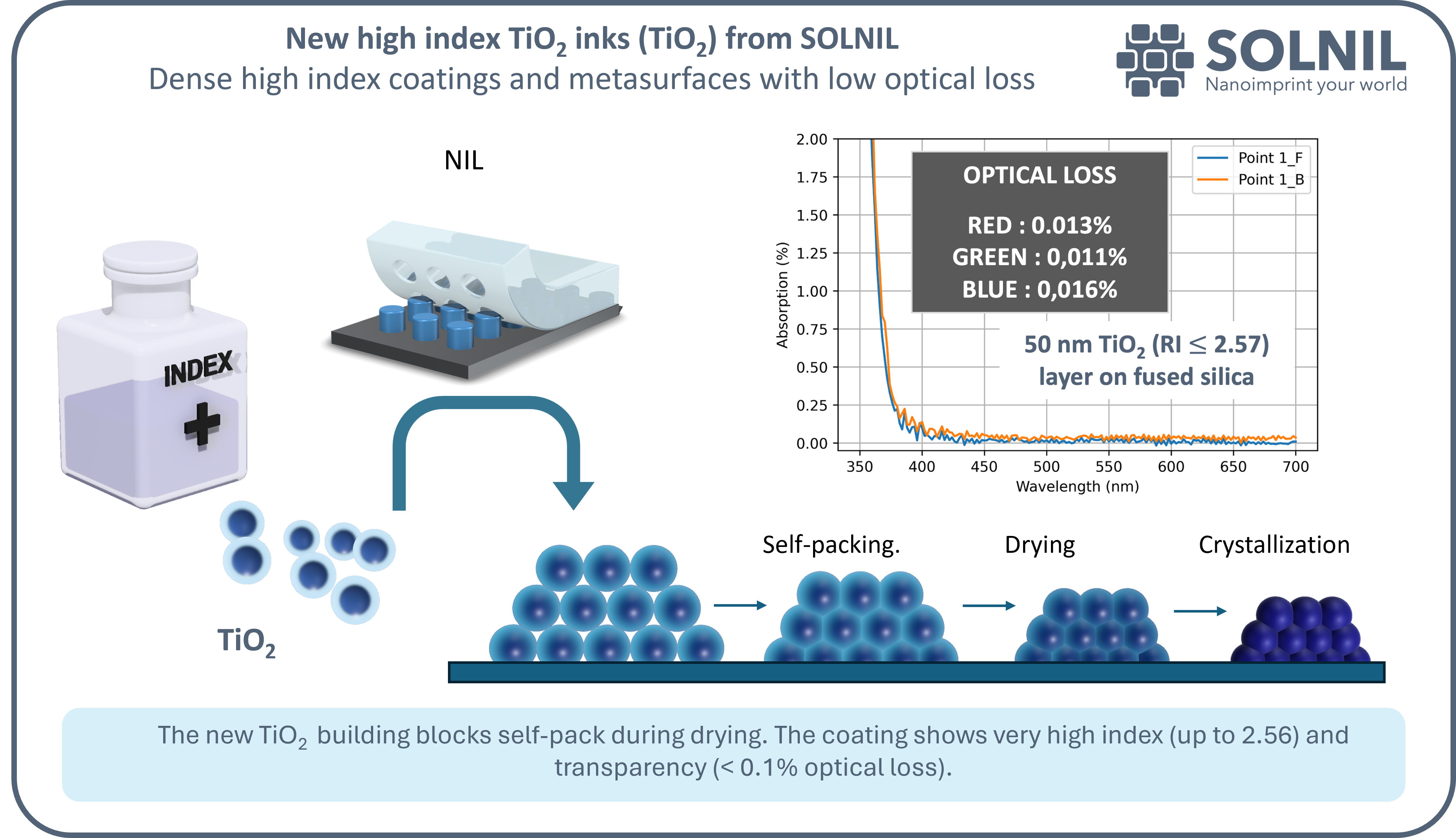

Solnil has developed original inks enabling the preparation of dense high index (2 < n@520nm < 2.6) TiO2 material with very high transparency (loss < 0.1%). The inks are suspensions of a new type of building blocks (CG-TiO2) that have the particularity of self-packing into a dense composite. After drying and curing, the final non-porous material is composed of dense packing of 6 nm Anatase crystals yielding high index and low scattering.

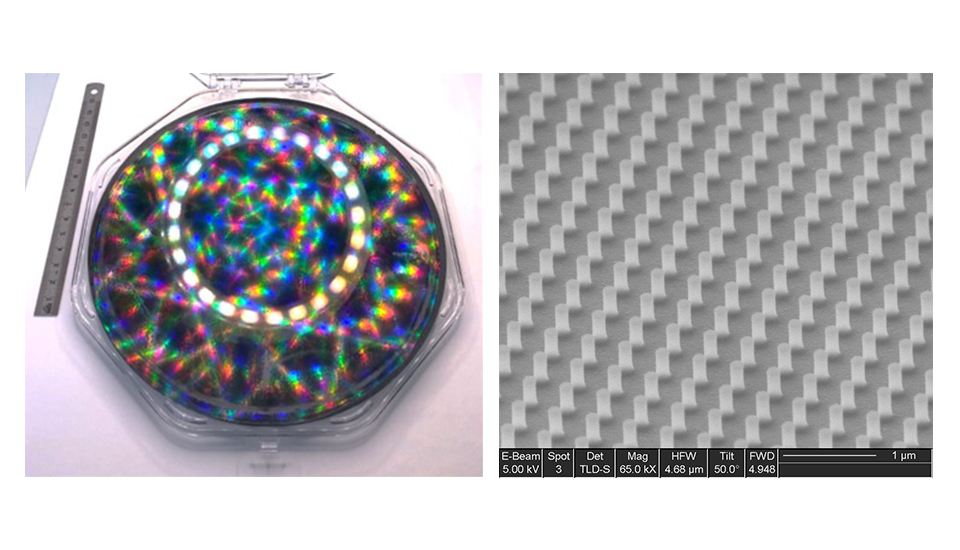

Obtaining a metasurface by MOx-NIL requires imprinting such inks (or other sol-gel formulations) when the building block are still mobile. Large surfaces can be processed with various oxides compositions and multiple feature morphologies, dimensions and high aspect ratio.